Komori Offset Printer

> Process > Komori Offset Printer

> Process > Komori Offset Printer

Various automation specification

Komori Printers reduce work burden of the operator, reduce production and delivery time, and develops total automation specification that excludes waste of various energies and resources in its application in each machine.

Komori reduces control mistakes, reduces time waste and promotes optimization of printing processes through high-precision automation specifications, such as the automatic plate changer (APC), auto cleaning device (ink, blanket), ink key free set device, paper size and thickness free set, ink part & absorption part remote control, etc.

Komori reduces control mistakes, reduces time waste and promotes optimization of printing processes through high-precision automation specifications, such as the automatic plate changer (APC), auto cleaning device (ink, blanket), ink key free set device, paper size and thickness free set, ink part & absorption part remote control, etc.

APC (Automatic PlateChanger / Automatic plate changer)

Komorimatic Water Supplier

The Komorimatic Water Supplier, developed with exclusive technology of Komori, is designed using the reverse-slip method, and forms a thin water film over the entire printing plate surface to minimize the use of volatile organic agents.

Komorimatic is the authentication device of Gold+Culion, the best certification bestowed by Japan’s E3PA (Environment Pollution Prevention Printing Association).

Komorimatic takes into consideration the health of the operator and the environment.

Komorimatic is the authentication device of Gold+Culion, the best certification bestowed by Japan’s E3PA (Environment Pollution Prevention Printing Association).

Komorimatic takes into consideration the health of the operator and the environment.

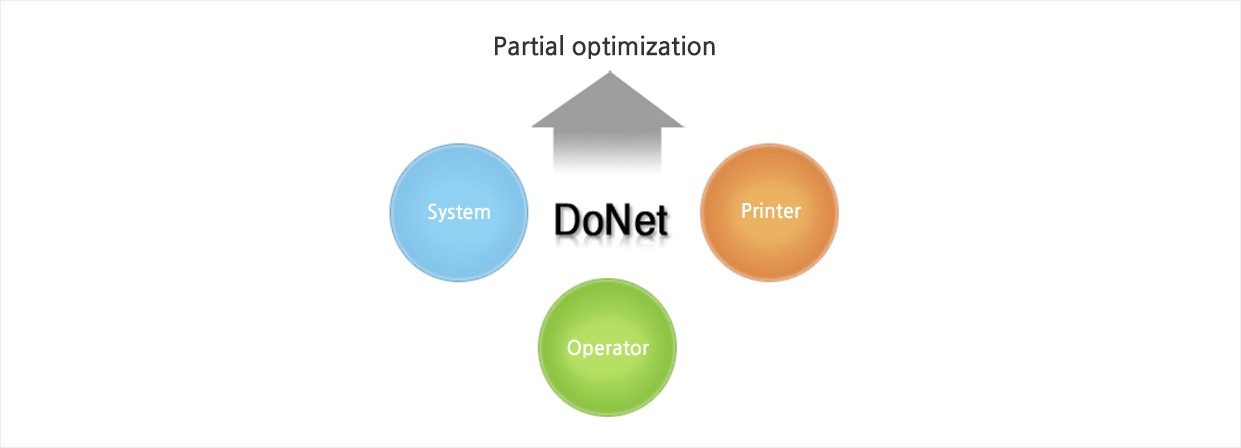

DoNet(Digital Open Architecture Network)

DoNet is a digital workflow concept that supports the printing standardization from the perspective of offset printers that are the final printing device of the processes from planning to printing.

DoNet adopts the global standard JDF format and establishes the digital workflow based on networks, and is comprised of software and devices that support the total optimization of printing from planning to the final process.

DoNet adopts the global standard JDF format and establishes the digital workflow based on networks, and is comprised of software and devices that support the total optimization of printing from planning to the final process.